KINGREAL UNIVERSAL IND., LTD.

Telefon

+86-13702855825PC injection molding is a kind of plastic processing technology. By heating PC raw materials to a molten state, injecting them into transparent PC injection molds for cooling and curing, the required plastic products can be obtained.

PC injection molding has the advantages of high production efficiency, stable product size and wide application range, and is widely used in automobile, electronics, household appliances, medical devices and other fields.

| 1 | Technological characteristics of PC injection molding |

| 2 | Process parameters of PC injection molding |

| 3 | Design and requirements of transparent PC injection molds |

| 4 | Main conditions of PC injection molding |

1. Technological characteristics of PC injection molding

PC has high viscosity, relatively high melting temperature and poor fluidity. Therefore, the PC injection molding needs to be controlled in the higher temperature range of 270-320C. Injection pressure has little effect on the fluidity of PC, but due to its high viscosity, it still needs a large injection pressure. In order to reduce the internal stress, the holding time should be as short as possible.

In addition, PC has a large shrinkage and good dimensional stability, but the internal stress of the product may also lead to cracking. Therefore, it is more suitable to improve fluidity by increasing temperature rather than pressure. At the same time, the risk of cracking can be further reduced by raising the optical-grade PC injection molds temperature, optimizing the transparent PC injection molds structure and improving the post-treatment. When the injection speed is low, defects such as ripples may occur at the gate, so it is necessary to control the temperature of the radiation nozzle separately and ensure that the transparent PC injection molds temperature is high enough, and at the same time reduce the resistance of the runner and the gate.

2. Process parameters of PC injection molding

Injection temperature: The choice of injection temperature needs to integrate the shape, size, optical-grade PC injection molds structure and product performance requirements. Generally, the temperature used in PC injection molding is between 270,320℃. If the material temperature is too high (such as over 340℃), the PC will decompose, the color of the product will become darker, and defects such as silver wires, dark stripes, black spots and bubbles will appear on the surface, and the physical and mechanical properties will also decrease significantly. The barrel temperature is usually controlled at 250320 (preferably not more than 350), and properly increasing the barrel temperature is beneficial to PC plasticization.

Injection pressure: Injection pressure has great influence on the physical and mechanical properties, internal stress, molding shrinkage, appearance and demoulding of PC products. Generally, the injection pressure is controlled between 80120MPa. For thin-walled, long-flowing, complex-shaped products with small gates, a higher injection pressure (120145MPa) is selected in order to overcome the resistance of melt flow and fill the optical-grade PC injection molds cavity in time.

Holding pressure and time: The holding pressure and holding time have great influence on the internal stress of PC products. The holding pressure is too small, the feeding effect is small, and vacuum bubbles or surface shrinkage are easy to appear; If the holding pressure is too high, large internal stress will easily occur around the gate. In actual processing, high material temperature and low pressure are often used to solve the problem. The choice of holding time should depend on the thickness of the product, gate size, optical-grade PC injection molds temperature, etc. Generally, small and thin products do not need long holding time, on the contrary, large and thick products should have long holding time.

Injection speed: the injection speed has no obvious influence on the performance of PC products. Except for thin-walled, small-gate, deep-hole and long-flow products, medium-speed or slow-speed processing is generally adopted, preferably multi-stage injection, and slow-fast-slow multi-stage injection is generally adopted.

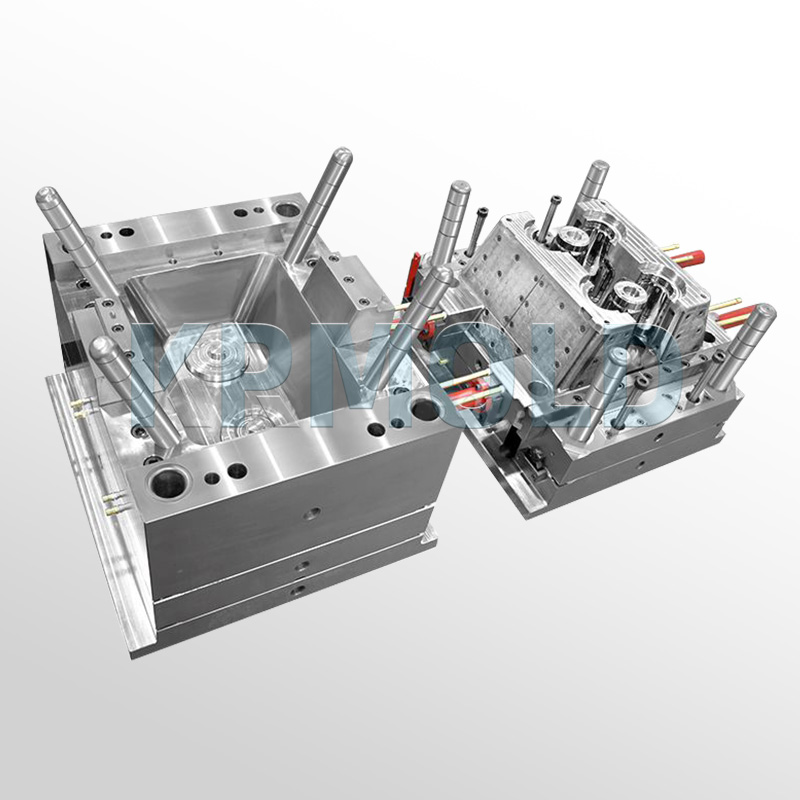

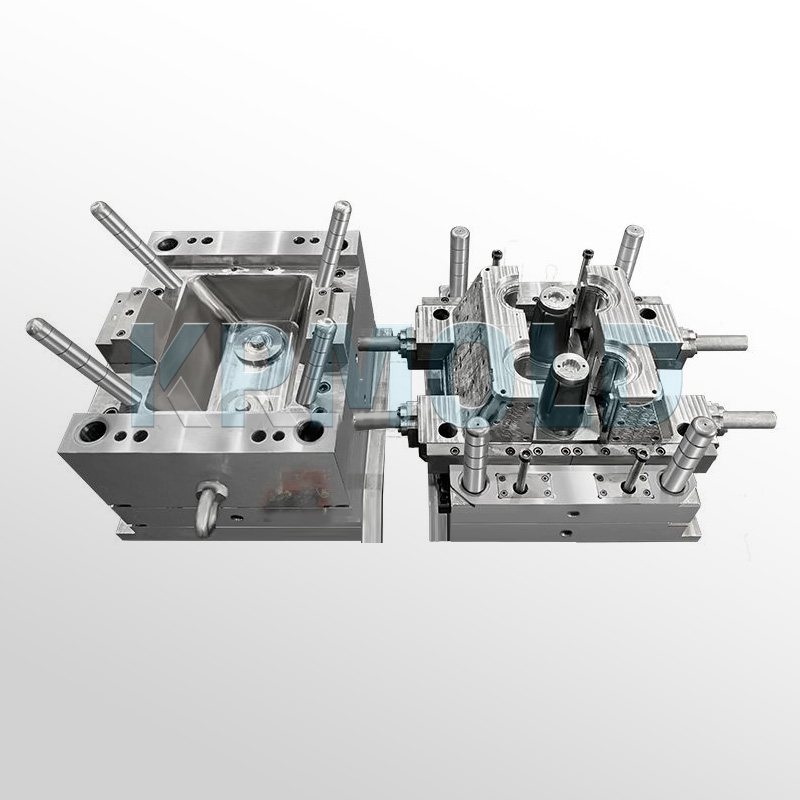

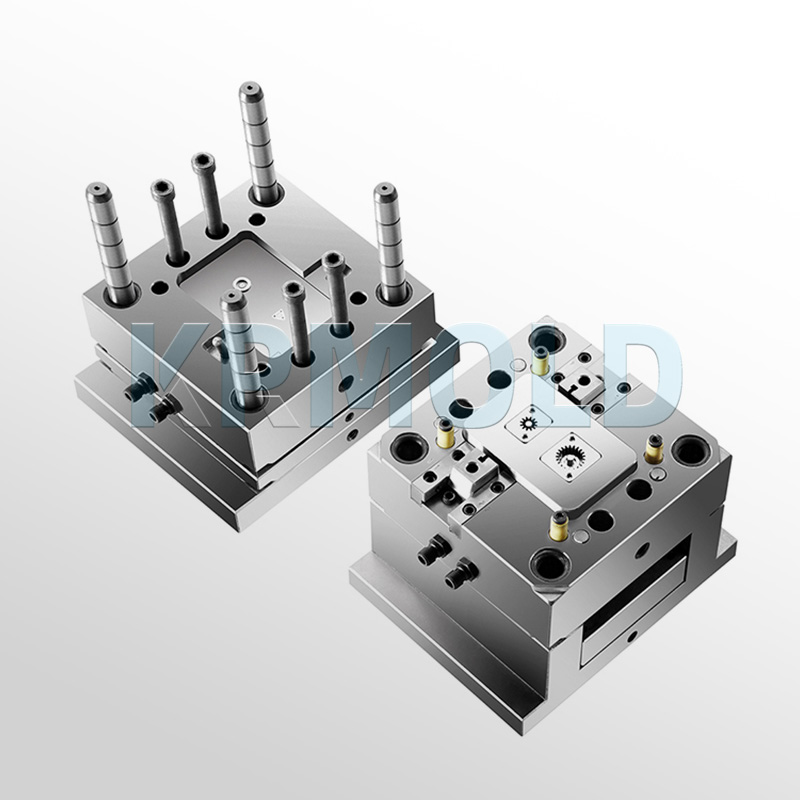

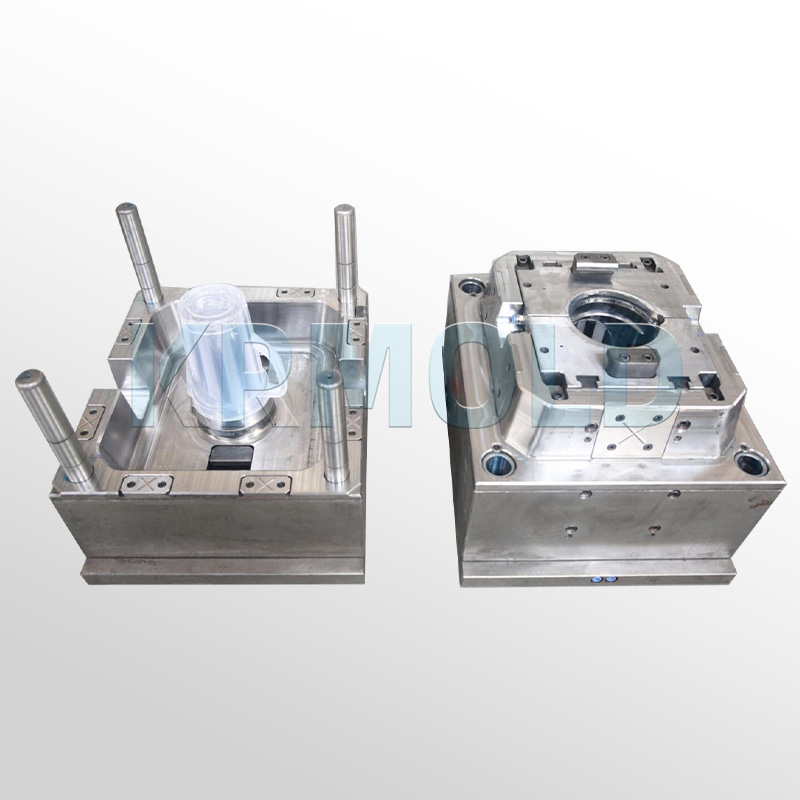

3. Design and requirements of transparent PC injection molds

Runner and gate design: the runner and gate of the optical-grade PC injection molds are required to be short and thick to reduce the pressure loss of fluid. The runner should be as short and round as possible, and the demoulding slope is generally about 30'-1. The gate can take any form, but the diameter of the water level is not less than 1.5 mm. For small products, needle gate can be used, and the depth of gate should be 70% of the thickest part; Other gates are circular and rectangular, and the larger the gate, the better, so as to reduce the risk of defects caused by excessive shearing of plastic.

Mold temperature: the transparent PC injection molds temperature should be controlled within the range of 85~120, and generally 80~100. For complex, thin and demanding products, it can also be raised to 100~120, but it cannot exceed the thermal deformation temperature of the optical-grade PC injection molds. High optical-grade PC injection molds temperature can reduce the difference between optical-grade PC injection molds temperature and PC material temperature, thus reducing the internal stress of parts.

4. Main conditions of PC injection molding

1) Temperature of the barrel. The barrel temperature has a great influence on the quality of plastic products. When the material temperature is low, it will cause material shortage, dull surface and silver wire. When the material temperature is high, it is easy to overflow, bubble and discoloration. Generally, the barrel temperature is controlled at 230~310℃. For thin-walled products, the cylinder temperature should be large; Small values can be taken for thick-walled products.

2) mold temperature. Under normal circumstances, the internal stress in plastic parts is roughly proportional to the difference between the transparent PC injection molds temperature and the material temperature during cooling, so the optical-grade PC injection molds temperature is required to be higher, which can be controlled at 80-120℃, 80-100℃ for thin-walled plastic products and 100-120℃ for thick-walled plastic products. If the optical-grade PC injection molds temperature exceeds 120℃, the cooling of plastic parts is slow, the optical-grade PC injection molds are easy to stick, the demoulding is difficult, the warpage is easy, and the molding cycle is long.

3) Injection pressure. The viscosity of PC melt is high, so it needs a large molding pressure. When screw injection molding machine is used, the injection pressure is generally 70~140MPa, while plunger injection molding machine is 100~160MPa. It can be determined according to the different conditions of raw materials, plastic products, transparent PC injection molds and injection molding machines.